- Home Page

- Company Profile

-

Our Products

-

Industrial High Pressure Pumps

- Industrial Polypropylene Centrifugal Pump

- Industrial Ammonia Transfer Pump

- Industrial Centrifugal Pump

- Industrial Monoblock Pump

- Industrial PVDF Moulded Pump

- Industrial Vertical Submerged Pump

- Industrial Multistage Pump

- Industrial Canned Motor Pump

- Industrial Vertical Glandless Pump

- Industrial Self-Priming Pump

- Industrial Ms Centrifugal Pump

- Industrial PTFE Pumps

- Industrial Pvdf Injection Molded centrifugal pumps

-

Industrial Pumps

- Industrial self priming pumps

- Industrial underground tank pumps

- Industrial uhmw-pe monoblock pumps

- Industrial Filterpress Unit Pumps

- Industrial effluent transfer pumps

- Industrial highly acidic transfer pumps

- Industrial mining industrial pumps

- Industrial ammonia transfer pumps

- Industrial low RPM pump

- Industrial effluent treatment pumps

- Industrial marine pumps

- Industrial storm water pumps

- Industrial Chemical Loading Pumps

- Industrial Non Metallic Centrifugal Injection Moulded Pump

- Industrial Horizontal Centrifugal Back Pull Out Metallic Pump

- Industrial Self Priming Chamber Type Pumps

- Industrial Industrial Monoblock Pump

- Industrial Multi Stage Self Priming Pumps

- Industrial Vertical Submerged Pumps

- Industrial Vertical Sealless and Glandless Pumps

- Industrial Ammonia Pump

- Industrial Sealless Magnetic Driven Pump

- Industrial Paper Mill Industries Pump

- Industrial Vertical Polypropylene Pump

- Industrial STEEL INDUSTRIES PUMPS

- IndustrialChemical Processing Industries Pumps

- Industrial Chemical Unloading Pumps

- Heavy Industrial Acid Transfer Pumps

- Industrial rain water transfer pumps

- Industrial SEWAGE PUMPS

- Industrial WASTE WATER TRANSFER PUMPS

- Industrial River Water Pumps

- Industrial irrigation pumps

- Industrial hcl transfer pumps

- Industrial hot water pumps

- Industrial SEA WATER PUMPS

- industrial water drainage pumps

- Industrial dirty water transfer pumps

- Industrial filterpress treatment pumps

- Industrial water treatment pumps

- Industrial FERTILIZER PUMPS

- Industrial THERMAL PLANT PUMPS

- Industrial ATOMIC POWER PUMPS

- Motorised Industrial Barrel Unloading Pumps

- Industrial frozen food plant pumps

- Industrial oil transfer pumps

- Industrial hazardeus liquid transfer pumps

- Industrial toxic liquid transfer pumps

- Industrial expensive liquid transfer pumps

- Industrial Chilling plant pumps

- Industrial ice plant pumps

- Industrial Cooling Tower Pumps

- Industrial organic chemical pumps

- Industrial Air conditioning pumps

- Industrial sprinkle system pumps

- Industrial sugar industries pumps

- Industrial High Temperature Pumps

- Industrial Effluent Treatment Pumps

- Industrial Recirculation Process Pumps

- Industrial photographic processing pumps

- Industrial pharmaceuitcal pumps

- Industrial Food Processing Pumps

- Industrial Perfume Transfer pumps

- Industrial Detergent Pumps

- Industrial Caustic Transfer Pumps

- Industrial petrochemical pumps

- Industrial Petroleum Pumps

- Industrial Pigment Transfer Pumps

- Industrial Paper Industries Pumps

- Industrial Pulp Transfer Pumps

- Industrial electroplating pumps

- Industrial Acid Pickling Pumps

- Industrial Acid Transfer Pumps

- Industrial metallic vertical pumps

- Industrial ms Vertical Pumps

- Industrial witt pumps

- Industrial cold storage pumps

- Industrial ammonia multi stage pumps

- Industrial meat processing plant pump

- Industrial Freon transfer pumps

- Industrial effluent pumps

- Industrial drum unloading pumps

- Industrial ETP PUMPS

- Industrial CI VERTICAL PUMPS

- Industrial vertical submersible dewatering pumps

- Heavy Duty Industrial Effluent Transfer Pumps

- Industrial Vertical submersible pumps

- Industrial vertical metallic pump

- Industrial portable submersible pumps

- Industrial vertical non metallic pumps

- Industrial hastelloy vertical pumps

- Industrial muddy water pumps

- Industrial pp vertical sump pumps

- Industrial pp vertical submerged pumps

- Industrial portable submersible dewatering pumps

- Industrial self priming multi stage

- Industrial dewatering pumps

- Industrial cs vertical sump pumps

- Industrial Low Pressure Vertical Pumps

- Industrial submersible water pumps

- Motorized Industrial CI Vertical Pumps

- Industrial multi stage centrifugal self priming pumps

- Industrial PVDF Vertical pumps

- Industrial multi stage pumps

- Industrial CS Vertical Pumps

- Industrial Pvdf Injection Molded Vertical Pump

- Industrial portable submersible dewatering monoblock pumps

- Industrial Hastelloy C Vertical Pumps

- Industrial multi stage self priming chamber type pumps

- Industrial Hastelloy B Vertical Pumps

- Industrial HDPE Vertical Pumps

- Industrial UHMW-Pe Vertical Pumps

- Industrial CF8 vertical pumps

- Industrial SS304 Vertical Submersible Pumps

- Industrial CF8 Vertical Sump Pumps

- Industrial negative suction pumps

- Industrial SS316 Vertical Submerged pumps

- Industrial barrel unloading pumps

- Industrial Duplex steel Vertical Pumps

- Copper Industrial Metallic Vertical Pumps

- Industrial MS Vertical Pumps

- Industrial High Pressure Vertical pumps

- Industrial HDPE CENTRIFUGAL PUMPS

- Industrial UHMW-PE CENTRIFUGAL PUMPS

- Industrial SS316 CENTRIFUGAL PUMPS

- Industrial SS304 CENTRIFUGAL PUMPS

- Industrial CF8 CENTRIFUGAL PUMPS

- Industrial CS CENTRIFUGAL PUMPS

- Industrial CI CENTRIFUGAL PUMPS

- Industrial HASTELLOY CENTRIFUGAL PUMPS

- Industrial HASTELLOY C CENTRIFUGAL PUMPS

- Industrial Hastelloy B centrifugal pumps

- Industrial DUPLEX STEEL CENTRIFUGAL PUMPS

- Industrial SINGLE STAGE CENTRIFUGAL PUMPS

- Industrial CHEMICAL PUMPS

- Industrial CHEMICAL PROCESS PUMP

- Industrial CHEMICAL TRANSFER PUMPS

- Industrial INDUSTRIAL PUMPS

- Industrial HIGH PRESSURE CENTRIFUGAL PUMPS

- Industrial LOW PRESSURE CENTRIFUGAL PUMPS

- Industrial MONOBLOCK PUMPS

- Industrial monoblock pumps

- Industrial MONOBLOCK BACKPULLOUT PUMPS

- Industrial MONOBLOCK CENTRIFUGAL PUMPS

- Industrial MONOBLOCK METALLIC BACKPULLOUT PUMPS

- Industrial MONOBLOCK METALLIC PUMPS

- Industrial MONOBLOCK NONMETALLIC PUMPS

- Industrial monoblock nonmetallic backpullout pumps

- Industrial pp monoblock pump

- Industrial pvdf monoblock pumps

- Industrial PP injection mouldede monoblock pump

- Industrial PVDF injection moulded monoblock pumps

- Industrial hdpe monoblock pumps

- Industrial SS316 monoblock pumps

- Industrial noiseless pumps

- Industrial vertical sealless pumps

- Industrial vertical glandless pumps

- Industrial SEALLESS & GLANDLESS PUMPS

- Industrial vertical sealless & glandless pumps

- Industrial vertical sealless metallic pumps

- Industrial vertical glandless non metallic pumps

- Industrial PP vertical sealless & gland pumps

- Industrial pvdf vertical sealless pumps

- Industrial pp injection molded vertical sealless pumps

- Industrial pvdf injection molded vertical

- Industrial hdpe vertical sealless pumps

- Industrial uhmw-pe vertical sealless pump

- Industrial ss316 vertical sealless & glandless

- Industrial cf8m vertical sealless pumps

- Industrial ss304 vertical sealless pumps

- Industrial cf8 vertical sealless pumps

- Industrial cs vertical sealless pumps

- Industrial ci vertical sealless pumps

- Industrial hastelloy vertical sealless pumps

- Industrial cf8m monoblock pumps

- Industrial ss304 monoblock pumps

- Industrial cf8 monoblock pumps

- Industrial cs monoblock pump

- Industrial CI MONOBLOCK PUMP

- Industrial cs monoblock backpullout pumps

- Industrial ci monoblock backpullout pump

- Industrial hastelloy monoblock pumps

- Industrial hastelloy c monoblock pumps

- Industrial Hastelloy b monoblock pumps

- Industrial Duplex steel monoblock pumps

- Industrial Metallic monoblock pumps

- Industrial MS monoblock pumps

- Industrial MONOBLOCK PUMP SET

- industrial monoblock pumps

- Industrial underground tank suction

- Industrial MS self priming pumps

- Industrial chemical Monoblock pumps

- Industrial chemical transfer monoblock pumps

- Industrial metallic self priming pumps

- Industrial duplex steel self priming pumps

- Industrial High Pressure Monoblock Pumps

- Industrial Hatealloy B self priming pumps

- Industrial Hastelloy c Self Priming Pumps

- Industrial Hastelloy Self Priming Pumps

- Industrial Low Pressure Monoblock pumps

- Industrial ci self priming pumps

- Industrial centrifugal self priming pumps

-

Industrial Mechanical Seals

- Industrial Wave Spring Seal (LIE 711)

- Industrial Single Spring Bellow Type Seal (LIE 705)

- Industrial Single Coil Spring Seal

- Industrial Agitator Seal

- Industrial Slurry Seal (LIE 703)

- Industrial Multi Spring Seals

- Industrial PTFE Bellow Seals

- Industrial Cartridge Seal

- Industrial Agitator Seal (LIE 708)

- Industrial Ptfe Bellow Seal Type (LIE 707)

- Industrial Cartridge Mechanical Seal (LIE 706)

- Industrial Single Spring Seal (LIE-702)

- Industrial Metal Bellow Seal (LIE 710)

- Industrial Textile Mechanical Seal (LIE 712)

- Industrial Multi Spring Seal (LIE-701 & LIE 701b)

-

Industrial Centrifugal Pumps

- Industrial Centrifugal Process Pump in Investment Casting

- Industrial Solvent Pump

- Industrial Chemical Processing pump

- Industrial Centrifugal Pumps

- Industrial Single Stage Horizontal Centrifugal End Suction Pumps

- Industrial Cooling Tower Pump

- Industrial Gland Packing Pump

- Industrial Pvdf Centrifugal Pump

- Industrial Metallic Centrifugal Pumps

- Industrial Oil & Gas Pump

- Industrial Back Pull Out Pump

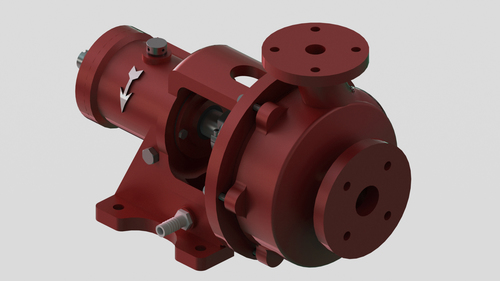

- Industrial High-Pressure Centrifugal Multistage Pump

- Industrial S.S. Centrifugal Monoblock Pump

- Industrial Pharma Industries Pump

- Industrial High Temperature Thermic Fluid Pumps

- Industrial Petroleum Industry Centrifugal Process Pump

- Industrial Polypropylene Pumps

- Industrial Vertical Pumps

- Industrial Thermosyphon System

- Industrial PVDF Centrifugal Pump

- Industrial Multistage Pumps

- Industrial Boiler Feed Pumps

- Industrial Self Priming Pumps

- Industrial Chemical Pumps

-

Industrial High Pressure Pumps

- Download Catalogues

- Contact Us

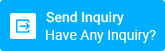

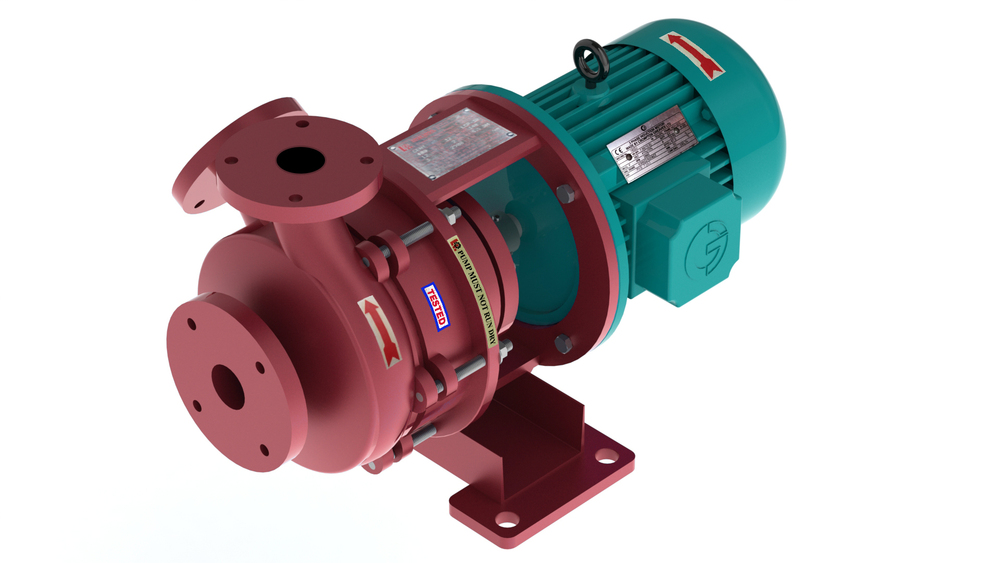

Industrial INDUSTRIAL PUMPS

Product Details:

- Theory Centrifugal Pump

- Features Sturdy Construction, Corrosion Resistant, Easy Maintenance

- Inlet/Outlet 1.5 inch / 1.25 inch

- Speed 1440/2880 RPM

- Noise Level Low

- Head Size Up to 40 Meter

- Max Suction 7 Meter

31000 INR/Set

X

Industrial INDUSTRIAL PUMPS Price And Quantity

- 1 Set

- 31000 INR/Set

- Deep Groove Ball Bearing

- Closed / Open

- Approximately 35 kg

- 2 meter

- Anti-corrosive Painted Finish

- TEFC (Totally Enclosed Fan Cooled)

- Air Cooled

- IP55

Industrial INDUSTRIAL PUMPS Product Specifications

- Horizontal, End Suction

- Single Stage

- Up to 80C

- Industrial, Commercial

- 60-3000 LPH

- Single Suction

- As per Pump Design

- ISI / ISO Certified

- Manual / Automatic

- 50 Hz

- Up to 6 Bar

- 220-440 V

- Base Mounted

- As per Model

- Self / Manual

- 7 Meter

- Mechanical Seal

- Cast Iron / Stainless Steel

- Up to 40 Meter

- Low

- 1440/2880 RPM

- Water, Chemical, Process Industry

- 1.5 inch / 1.25 inch

- As per Model

- Electric

- Centrifugal Pump

- Sturdy Construction, Corrosion Resistant, Easy Maintenance

- 0.5 HP - 10 HP

- Deep Groove Ball Bearing

- Closed / Open

- Approximately 35 kg

- 2 meter

- Anti-corrosive Painted Finish

- TEFC (Totally Enclosed Fan Cooled)

- Air Cooled

- IP55

Industrial INDUSTRIAL PUMPS Trade Information

- MUMBAI

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- 30 Set Per Week

- 2 Week

- Contact us for information regarding our sample policy

- Fumigated Wooden Boxes

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- ISO 9001 : 2015 , MSME , SMERA , NSIC , D & B , Ex ATEX ,ISO 2858 DIN 24256 , B 73.1 , ISO 5199

Product Description

* SOLVENT * ACID TRASNFER* COOLING TOWERS* FILTER PRESS * HEAT EXCHANGER* PAPER AND PULP* FOOD PROCESSING* CHILLING PLANT* EJECTOR SYSTEMS* SLURRY TRANSFER* IRRIGATION* MARINE* MINING AND MINERAL* OIL AND GAS* POWER PLANT* SUGAR PLANT* WATER TREATMENT* FERTILIZER * EFFLUENT * AIR CONDITIONING* DYES AND PIGMENTS* PHARMACEUTICALS* PICKLING PLANT* SPRINKLE SYSTEMAdvanced Pumping Technology

Our industrial pumps integrate centrifugal theory and air-cooled systems with TEFC enclosures to deliver high efficiency and protection. Designed to handle aggressive environments, they offer smooth performance due to the deep groove ball bearings and robust construction. Each unit is engineered for both self and manual priming, making them versatile for various operational requirements.

Customized for Industrial Applications

With flow rates between 60 and 3000 LPH and head delivery up to 40 meters, these pumps can be tailored to fit specific industrial or commercial needs. Supported by ISI and ISO certification standards, they are suitable for handling water, chemicals, and process media, with material options in cast iron and stainless steel for corrosion resistance and longevity.

Ease of Use and Maintenance

Thanks to user-friendly design features such as base mounting, manual or automatic controls, and low noise operation, these pumps are easy to install and maintain. Mechanical seals and a strong anti-corrosive finish ensure minimal downtime and extend operational life, making them a reliable choice for any industrial setup.

FAQs of Industrial INDUSTRIAL PUMPS:

Q: How does the self-priming feature of the industrial pump work?

A: The self-priming feature allows the pump to evacuate air from the suction line automatically, enabling it to begin pumping fluids without the need for manual priming. This feature simplifies start-up and is especially useful when frequent starts or stops occur in your application.Q: What types of fluids can these pumps handle effectively?

A: These pumps are engineered for versatility and can efficiently handle water, a variety of chemicals, and other process industry fluids. Their corrosion-resistant construction and mechanical sealing systems make them suitable for handling both clean and slightly contaminated fluids.Q: When should an open impeller be chosen over a closed one?

A: An open impeller is typically chosen when handling fluids containing solid particles or slurries because it is less likely to clog. Closed impellers, on the other hand, are more efficient for clean liquids and provide higher pressure and flow efficiency.Q: Where can these pumps be installed?

A: These industrial pumps are base-mounted and designed for use in facilities such as industrial plants, commercial buildings, water treatment plants, and chemical processing sites. Their compact horizontal structure allows for flexible installation in standard pump rooms or dedicated process lines.Q: What benefits do deep groove ball bearings provide in these pumps?

A: Deep groove ball bearings offer enhanced load capacity, reduce operational friction, and contribute to longer service intervals. Their robust design supports smooth, reliable operation even under demanding industrial conditions, minimizing maintenance costs and downtime.Q: How is maintenance handled for these pumps?

A: Routine maintenance is simplified thanks to easy access to major components like the impeller, seals, and bearings. The mechanical seal and anti-corrosive painted finish further reduce wear and maintenance frequency, allowing for longer, trouble-free operation.Q: What is the typical process for selecting the right model?

A: Selecting the correct pump model involves assessing required capacity, head size, suction conditions, material compatibility, and intended fluid type. Manufacturers and suppliers assist by matching these criteria to ensure optimal pump efficiency and longevity for your specific application.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Pumps' category

|

LEAKLESS (INDIA) ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |